Complex Jackshaft alignment made simple with experience and an Easy-Laser XT660 Shaft Alignment Tool

When you are working with nature, you treat it with respect. And that’s what this dam facility on the Kootenay River in British Columbia does (image, above left). When you harness the power of a river you need your control systems to work. The spillway gates control the level of the dam and in this example, it is lifted and lowered by two Worm Drives that are approximately 33 feet apart, so it’s a large gate. Pictured (above right) is one of the worm drives.

Read more

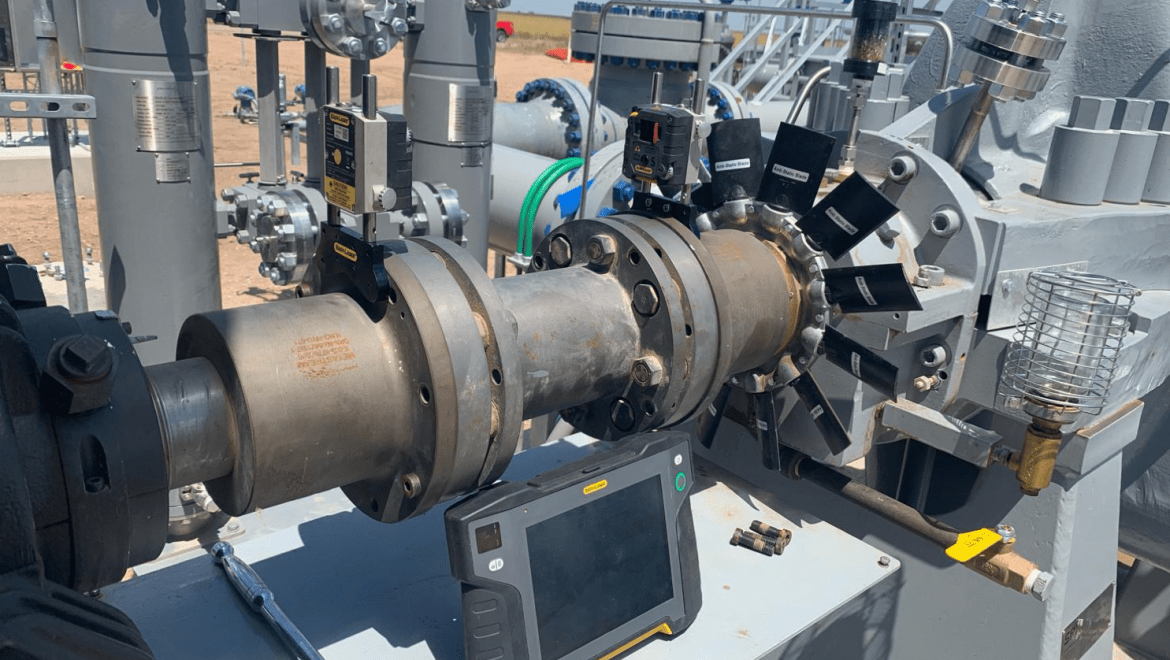

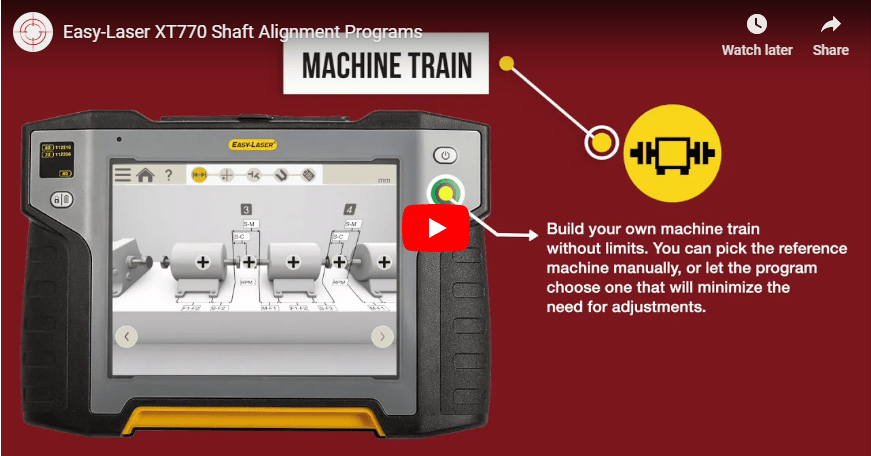

Let us review this case study on a common issue when working on a pump and motor alignment done by Brian Franks, Owner and Field Service Technician of JetTech Mechanical (www.jettechmechanical.com).

Let us review this case study on a common issue when working on a pump and motor alignment done by Brian Franks, Owner and Field Service Technician of JetTech Mechanical (www.jettechmechanical.com).