How Belt Alignment Can Optimize Your Business Operations

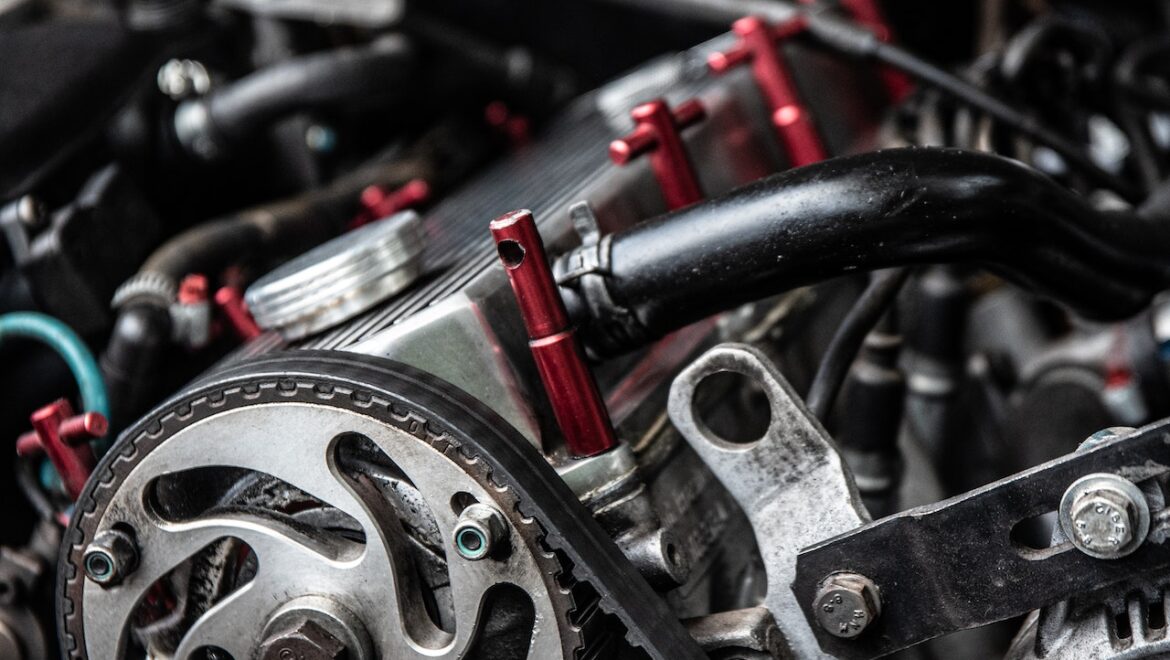

Belt, Pulley, or Sheave alignment applications and the tools used to maintain them form an integral part of many industries, ensuring all machine and equipment elements are as accurate, reliable, and long-lasting as possible.