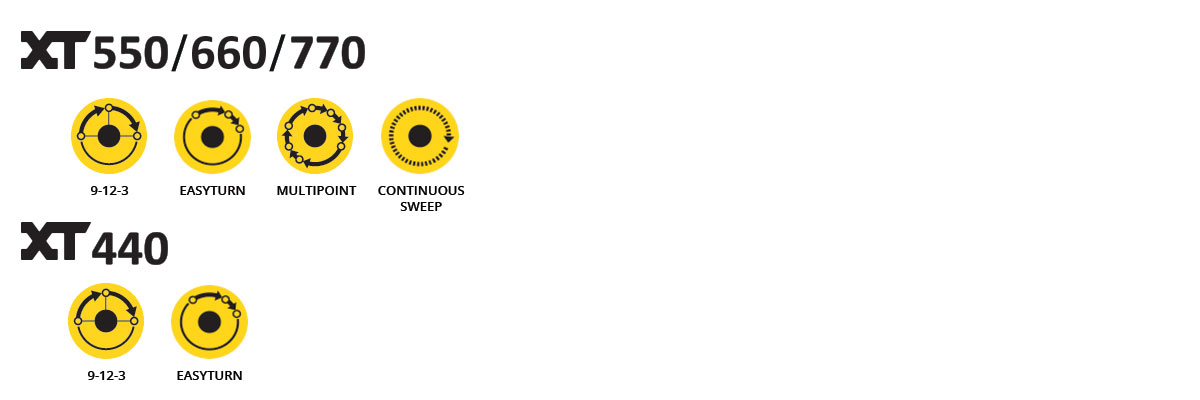

Shaft Alignment Methods are different ways to align your machines depending on your application and machine set up.

For Generation XT Smart Functions click here.

For Generation XT Programs click here.

Alignment & Measurement Experts

We are Easy-Laser’s Canadian National Distributor