Parallelism Measurement

Parallelism measurement is often carried out between rolls and other surfaces in many machines of the paper, metal, converting and printing industries. In the manufacturing industry, the production equipment often depend on rolls as the carriers of the material web. Parallel misalignment may cause the roll to stretch the web unevenly, deform it and sometimes even break it. This can lead not only to quality problems, but also unnecessary machine breakdowns and hours (in worst case days) of costly downtime.

Making sure objects are parallel to each other is also important for a well functioning installation of press machine tables, rails, overhead tracks and metal sheet cutting machines.

Drawbacks of Conventional Parallelism Measurement Methods

Some companies are still using old technology to perform a parallelism measurement. But these methods have numerous drawbacks. Using optical systems such as theodolites or telescope bars is time-consuming, often expensive and doesn’t really do the job. The machine geometry also makes it difficult to use these methods. Machine parts become an optical barrier for the theodolite bar while large distances between surfaces can make the use of telescope bars a real challenge.

How to Measure for Parallel with a Laser Beam – Traditional Method

In laser alignment, a red laser beam is the reference to which the parallelism is measured. Compared to old technology, the work is done much faster, easier and more accurately. The laser beam has no weight or volume. The system is compact, flexible and simple to use whenever the need arises. The versatile design allows production teams to solve the manufacturing problems quickly on-site. This will reduce unnecessary machine breakdown and costly downtime. It’s also possible to identify misalignment in time, before there’s a breakdown, and carry out preventative maintenance work. To be able to present documentation of the alignment job is a benefit for many users. Another advantage is that laser systems can be used for many other alignment jobs, such as flatness measurement of wire sections (suction boxes) and shaft alignment of drive units. This makes it a very cost effective investment for the maintenance department.

In laser alignment, a red laser beam is the reference to which the parallelism is measured. Compared to old technology, the work is done much faster, easier and more accurately. The laser beam has no weight or volume. The system is compact, flexible and simple to use whenever the need arises. The versatile design allows production teams to solve the manufacturing problems quickly on-site. This will reduce unnecessary machine breakdown and costly downtime. It’s also possible to identify misalignment in time, before there’s a breakdown, and carry out preventative maintenance work. To be able to present documentation of the alignment job is a benefit for many users. Another advantage is that laser systems can be used for many other alignment jobs, such as flatness measurement of wire sections (suction boxes) and shaft alignment of drive units. This makes it a very cost effective investment for the maintenance department.

Benefits of Laser-based Alignment Systems for Measuring for Parallel

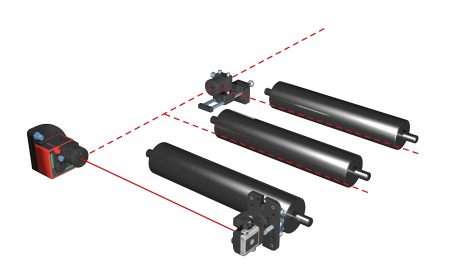

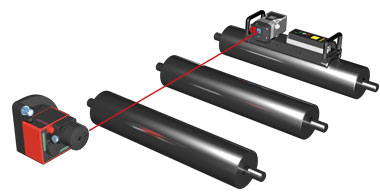

The laser beam is directed along the machine, but perpendicular to the measurement object. The principle for parallelism measurement is based on the beam being deflected at 90° by a penta prism. In this way it is possible to measure a large number of objects on long machines by moving the penta prism along the machine in the direction of the laser beam. The detector is moved to the front and rear end of the measurement object.

The laser beam is directed along the machine, but perpendicular to the measurement object. The principle for parallelism measurement is based on the beam being deflected at 90° by a penta prism. In this way it is possible to measure a large number of objects on long machines by moving the penta prism along the machine in the direction of the laser beam. The detector is moved to the front and rear end of the measurement object.

A completed measurement shows the mutual parallelism of the measurement objects in relation to the base line or one of the measurement objects, graphically and digitally. Any roll or base line can be used as reference. The Easy-Laser® E970 Parallelism is an example of a system based on this principle.

We are Canada’s Master Easy-Laser Distributor

Resources

Parallelism