Measurement Programs are specific to your application whether your aligning a horizontal or vertical machine; they are intuitive and guide you easily through alignment process.

For Generation XT Smart Functions click here.

For Generation XT Measurement Methods click here.

Horizontal Machines

For the shaft alignment of horizontal machines. The user interface is intuitive and guides you through the measurement process. It is animated and zooms into the most important things for each step. You can save the measurements of a machine for As found and As left in the same file.

Softfoot Check

start the shaft alignment work by performing a soft foot check to ensure the machine is resting evenly on all its feet. This is necessary for a reliable shaft alignment. The program shows which foot (feet) should be corrected. After the soft foot check is complete you can go directly to the alignment program with all of the machines distances saved.

Vertical/Flange-Mounted Machines

For the shaft alignment of vertical and flange-mounted machines. Just like the horizontal machines program for shaft alignment, the user interface is intuitive and guides you through the measurement process.Values - Digital Dial Indicator

The extremely useful Values program can be used as a digital dial indicator as live time readings are shown on the S- and M- units. It has a clear digital representation of the laser target, and a list view for recorded values. For example, you are able to check for bearing play or shaft load by electronically zeroing the units and then moving the machine to see what movement occurs.

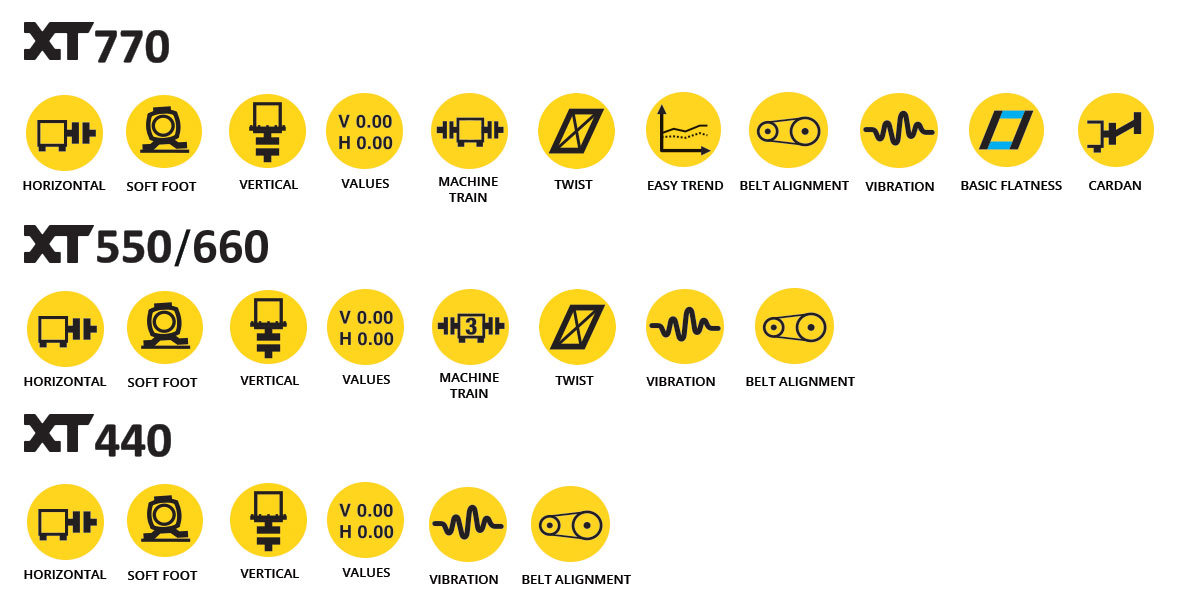

Machine Train (XT770)

Build your own machine train without limits. You can pick the reference machine manually, or let the program choose one that will minimize the need for adjustments.

Machine Train (3) (XT550 & XT660)

Build your own machine train, up to 3 machines. You can pick the reference machine manually, or let the program choose one that will minimize the need for adjustments.

Machine Base Twist

The twist measurement program allows you to check the flatness or twist of the machine foundation using only the measuring units in the system.EasyTrend

With the EasyTrend program you can keep track of machine movement over time. For example, you can check for thermal expansion in an offline-to-running or running-to-offline condition. (Requires additional DM-brackets.)

Belt Alignment

Align your sheaves and pulleys with digital precision. Adjustment of the machines is displayed in real time on the screen, with readings for angle and axial displacement in both the vertical and horizontal axes, as well as an adjustment value for the front or rear foot pair. (Requires the Pulley Alignment Tool XT190 BTA accessory.)

Vibration

Using the vibration program you can diagnose vibration levels, imbalance, misalignment and looseness. The direct readout of 1x, 2x, 3x RPM, total level as well as bearing condition provides necessary information during installation and alignment. (Requires the Vibration Measurement Tool XT280 accessory.)

Cardan/Offset Mounted Machines

For alignment of cardan/offset mounted machinery. (Requires additional Cardan bracket kit.)

Basic Flatness

With this program you can check the flatness of foundations and frames, using two rows of points, 2 to 8 points per row. Separate laser transmitter required. (Requires Geo Kit).