Bore Alignment - the Easy Way

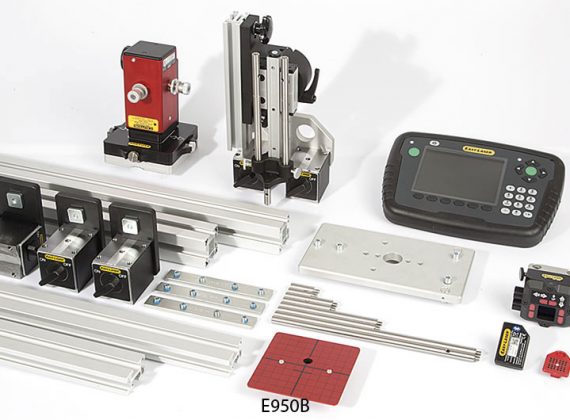

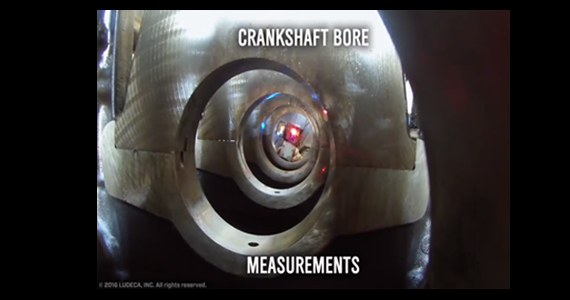

The E950 Bore alignment tool by Easy-Laser® makes checking and aligning bores, bearings and bearing journals easier thanks to its wireless detectors and versatile brackets. A large colour display with clear graphics and software that guides the user through the entire measurement process contributes to simple operation. The Bore alignment tool automatically calculates the bores/bearing journals in relation to each other, both horizontally and vertically. You can then evaluate the results directly on-site with different calculation methods such as Best fit around zero and Waviness. It is also possible to analyze the different choices of reference points and set the offset and tolerance values. One new feature is checking for ovality, for example, to analyze the wear rate. The bore alignment tool takes care of all these complicated calculations for you. You measure and align both full and half bearing journals with equal simplicity. The wireless detector eliminates uncertain factors such as cable pull. All parts are designed for maximum accuracy and stability, and measure with a resolution of 0.001 mm [0.05 mils]. Measurement distance up to 40 m [130 feet]. Easy-Laser® E950 bore alignment tool is suitable for use both in production and out in the field.

EASY-LASER® E950-A, E950-B, E950-C AND E950 Bore alignment tools

We offer four versions of the bore alignment tool.

- Easy-Laser® E950-A bore alignment tool is primarily used for diesel engines (for example crank and camshaft bearings), gearboxes, compressors and similar applications that have medium bore sizes (5.51″-19.68″). Positioning workpieces in machine tools is also an appropriate application.

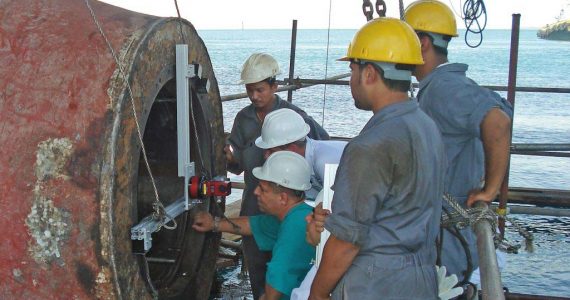

- Easy-Laser® E950-B bore alignment tool is primarily used for propeller shaft installations on ships with stern tubes, support bearings, gearboxes and engines with bore sizes between 11-81″-39.37″.

- Easy-Laser® E950-C bore alignment tool is primarily used for diesel engines (for example crank and camshaft bearings), gearboxes, compressors and similar applications that have smaller bore sizes (3.15″-19.68″). Positioning workpieces in machine tools is also an appropriate application.

- Easy-Laser® E950-D bore alignment tool is primarily used for propeller shaft installations on ships with stern tubes, support bearings, gearboxes and engines with larger bore diameters (11.81″-47.24″).

We are Easy-Laser’s Canadian National Distributor

Resources

E950