BELT, CHAIN & PULLEY ALIGNMENT

A common misunderstanding is that belt drives are not affected dramatically by misalignment. This assumption has cost the industry a huge amount in unnecessary replacement of sheaves/pulleys, sprockets, belts and chains etc. Also several investigations have shown savings up to 10 % in energy costs alone!

One of the objectives during the installation is to remove any unwanted stress from the machine units. We can do this by aligning the belts correctly. This will give the optimum operating life for the belt but also the machine. To align the belt you have to correct the offset and angular misalignment in both the Horizontal and Vertical planes.

Angular misalignment in the horizontal plane (toe-out and toe-in).

Parallel misalignment (offset) in the horizontal and vertical planes.

Angular and parallel misalignment in both planes. This is normally what we are trying to correct.

Belt drives with several wide belts are especially sensitive. It is easy to understand that the difference in belt tension between the inner and outer belts can differ greatly when aligned incorrectly. This reduces efficiency as not all belts are driven optimally. If one belt is worn then all belts must be replaced with new ones at the same time, which adds expense to the entire operation. Extending service life of belts thanks to correct alignment is easy.

Whichever of our belt sheave laser alignment tools you choose it usually pays for itself within a few months. Below on the left: Easy-Laser D90 BTA – Visually read targets. Possible to add digital detectors. Below to the right: Easy-Laser XT190 BTA BTA – Standalone wireless Bluetooth digital belt alignment system. Can also be used with E51 Display (ie. E540 and E710 shaft alignment systems), XT11 Display (ie. XT440/XT660 Shaft alignment systems), and any Android/Apple phone/tablet (with the XT Alignment app.)

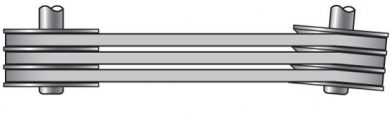

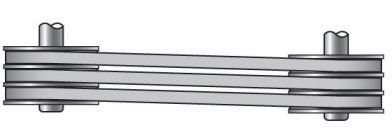

Side Mounting for Greater Accuracy

Easy-Laser® uses the pulley’s side surface as reference during alignment. This gives greater accuracy, as the mounting surface for the tool is larger than if the tool was mounted against the radial surface. Any faults and damage on the pulley affect the result less on the side (see image). The risk of wear and damage on the pulley is obviously greater in and by the groove where belts run. A further advantage is that without extra accessories, all types of pulleys can be aligned, regardless of belt type. It is even easy to compensate for pulleys of varying widths. Magnetic mountings on lasers, detectors or targets make it easy to install the equipment. Even non-magnetic pulleys can be aligned as the units are extremely light and can be mounted against the side, secured by double-sided tape.

The Advantages of Lasers Compared to Traditional Technology

Using lasers makes work faster and easier than with traditional methods such as String or straightedge. These methods usually require two people to carry out the work, one to hold the straighedge and one to adjust the machine. Spotting small differences with the naked eye using these methods is both arbitrary and dependent on who is performing the alignment. Laser alignment and measurement systems are considerably easier to read. In addition, they are much more accurate.

From the belt manufacturer’s side, it is sometimes recommended that there is a maximum angular error between the pulleys of 0.5 to 0.25 degrees for optimal service life and efficiency. Such small angles cannot be seen with the naked eye without the assistance of a laser.

The Advantages of Lasers Compared to Traditional Technology

Increases availability and productivity of the machine = assured production

Increased service life of belts, pulleys and bearings = fewer removals of replacement parts

Optimally utilized lubricant film = less risk of overheating and secondary damage

Reduced friction = lower energy consumption

Less vibration = reduced noise level

Less risk of serious breakdowns = safer working environment

Greater overall savings with fewer spare parts, lower energy consumption and less unscheduled downtime.

We are Canada’s Master Easy-Laser Distributor

Resources

Parallelism