3 Signs Your Gearbox, Pump And Motor Shafts Are Not In Alignment

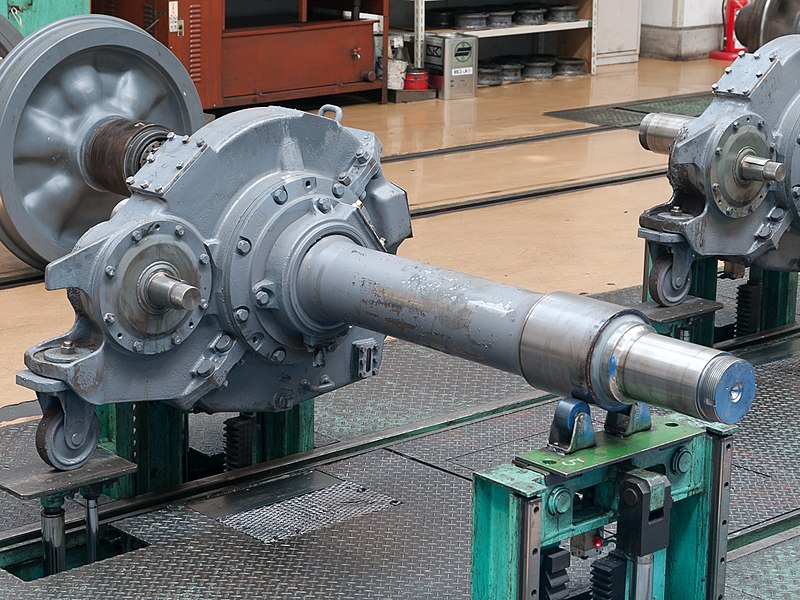

If your machine’s gearbox, pump and motor shafts are not in alignment, the cost of failures and repairs can be drastic. Misalignment of this nature will significantly reduce its performance and mean time between repairs, as well as the functional longevity of the gearbox, motor, and the machines as a whole!