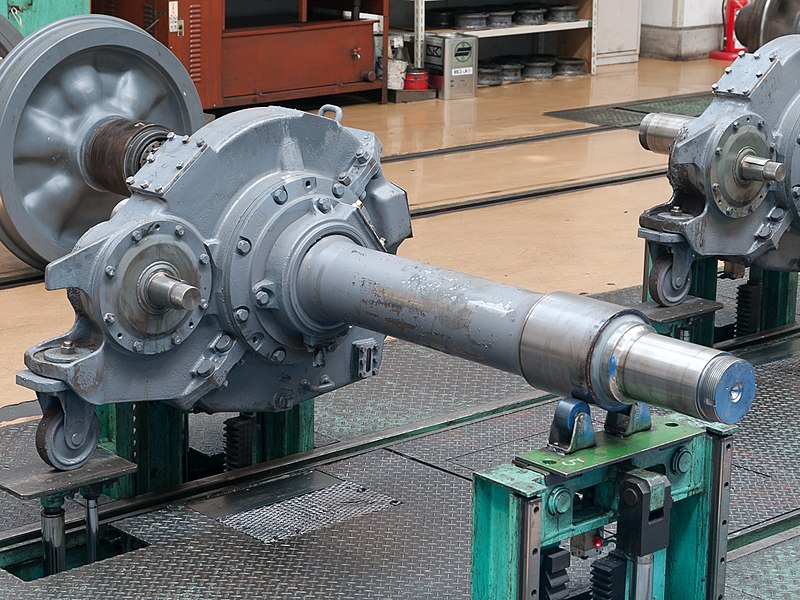

Belt, Pulley, or Sheave alignment applications and the tools used to maintain them form an integral part of many industries, ensuring all machine and equipment elements are as accurate, reliable, and long-lasting as possible. When dealing with side-to-side movements, the slightest off-angle could result in mass wear and tear or even a major breakdown, which means you’ll need to dig into your pockets to replace or repair damaged equipment.

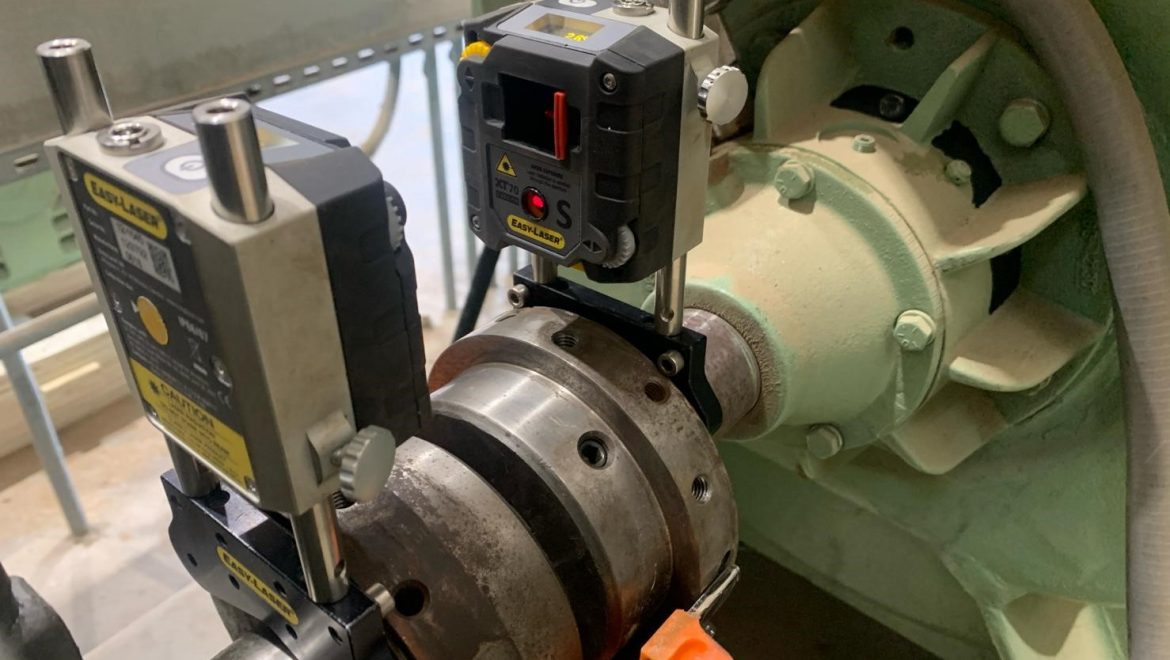

Although there is a common misconception that aligning your systems is no big deal, “it’s just a rubber band, right,”the proof is in the pudding when professionally laser aligned machines long outlast those without alignment or those using traditional methods.As these systems need to take into account the tolerances and strength of the moving piece components, a moreaccurate measurementtool is needed, and that’s where laser belt alignment tools come in.

What Are the Primary Advantages?

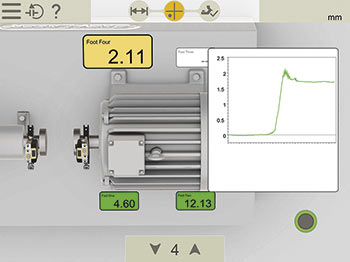

When using more traditional methods, your results are far more likely to be affected by the human factor. With a digital, light-based design that is not affected by the individual engineer’s or mechanic’s eyesight, you can achieve a far more accurate and data-driven view of the overall situation.

Cutting wood at the proper angle is a simple example of how human judgement is frequently incorrect. Let’s assume you need to cut a piece of wood at a 45-degree angle for your child’s school project. Would you be able to cut it with precision using only your judgement? Probably not! Instead, you rely on various tools to ensure the wood is cut evenly and correctly, avoiding mistakes entirely, which saves you plenty of time and money.

This is why laser belt alignment tools are an inexpensive investment for your business that quickly pays for itself, in part through reduced energy consumption and less breakdowns. It is a recommended action when you need to rely on the efficiency of your machines or equipment elements.

What’s the Deal With Misalignment?

When misalignment occurs, there are several ways in which wear and tear can occur that put your machines at risk. From breakdowns to other peripheral issues that may be caused, not having the correct orientation and alignment of your pulleys and sheaves can result in major issues for your production.

Three distinct types of skew orientation can occur, and these will bring with them specific levels of damage. Horizontal shifts usually mean that one of the sheaves has rotated, resulting in the belt being pulled at an angle, meaning the element is constantly worn down. Next is the vertical shift, which indicates that the unit or element has tilted up or down, allowing the moving parts to twist as they run and adding increased pressure where there shouldn’t be any. The last is the axial offset, which is when one sheave extends out further than the other, creating a diagonal path and increased wear and tear.

Laser belt alignment tools play integral roles in the efficiency and longevitty of machines and industrial processes everywhere.