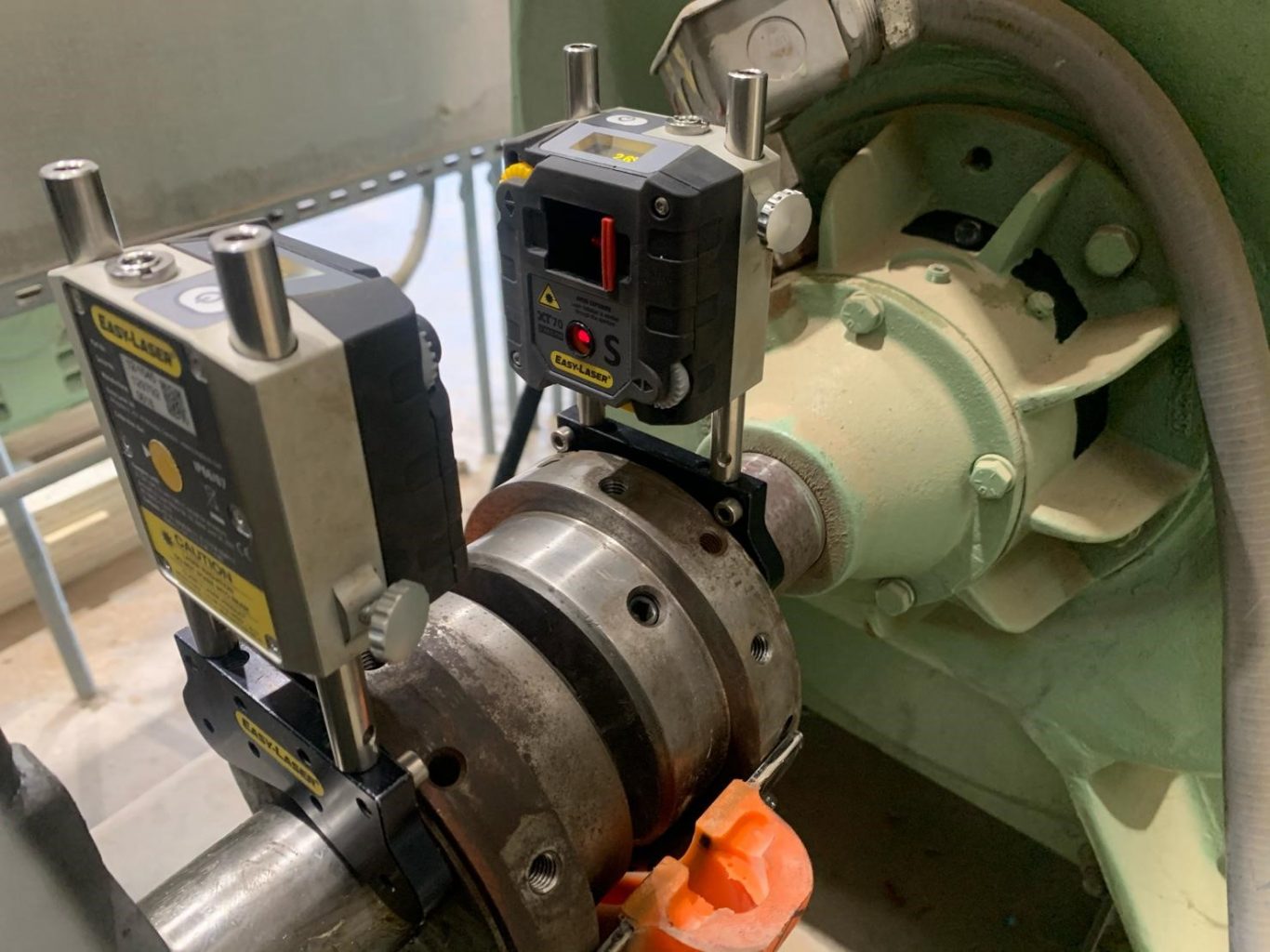

Troubleshooting Looseness When Using A Laser Alignment Tool For Shafts

At times, shaft alignment can become extremely frustrating almost as if it is possessed with a mind of its own. One set of readings may indicate that you make adjustments one way, the next set of readings then indicates something completely different. Quite simply, and almost without fail, if there are repeatability issues then something is loose with the laser alignment tool or there is some mechanical play. At BENCHMARK PDM we know how important it is to have a laser alignment tool for shafts that you can rely on to fix the problem and we pride ourselves on offering nothing but the best for your alignment needs.

Assessing Detector Movement

Here are some simple questions to work through to try and diagnose and address issues with looseness:

- Are the chain brackets tight to the shaft or hub?

- Are the detectors tight to the rods?

- Are the extension rods tight to the brackets?

- Is the sensor rubbing on something when positioning the shaft?

- When using magnetic brackets, do the magnets have full contact to prevent them from slipping?

- Did you bump something out of place?

Assessing Coupling / Bearing Play

Here are some simple questions to work through to try and diagnose and address issues with mechanical looseness or play:

- Are all the hold down bolts on all pieces of equipment tight?

- If it is mounted to a hub instead of the shaft, is the hub tight to the shaft?

- For sleeve bearings, has the shaft come to rest so you know for sure it’s in the same spot for measuring?

- Is there coupling play or backlash?

- Is there any bearing play?

- For all the above, did you double check and are you sure?

Other Diagnostic Factors To Consider

There may still be base or foot movement that is causing looseness or it could be a torsional movement issue. Simply, you will be able to tell by addressing the operation of the machine to ascertain:

- If the feet are moving relative to the base

- If the base is moving relative to the feet

- If there is debris around the shims and base

- If multiple shims can be consolidated

Torsional movement addresses looseness in the coupling, whether it is being controlled in a consistent manner, if the backlash in the gearing is being controlled, and if the chain or magnetic brackets are fitted tight to the shaft or hub.

Building Lasting Relationships That Better Service Your Machine Assets

At BENCHMARK PDM, we place high value on the relationships we have with our clients. We are a family owned and operated business and we extend that commitment to our customers. We ensure that all our staff are highly trained and ready to answer any questions you may have. Contact us today to address any queries or to order your laser alignment tool for shafts. You can reach us by telephone on +1-800-598-1117, e-mail us on info@benchmarkpdm.com, or fill in our contact form here. Whether you have a product or training related query, or whether you want to address a machine application issue, our friendly team is here to help. We look forward to hearing from you!

0 comments

Write a comment