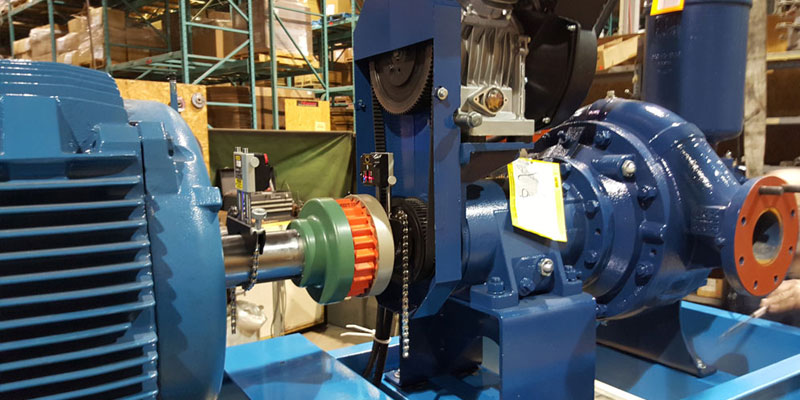

Benchmark PDM present new measurement & alignment system at the 2016 EASA Convention

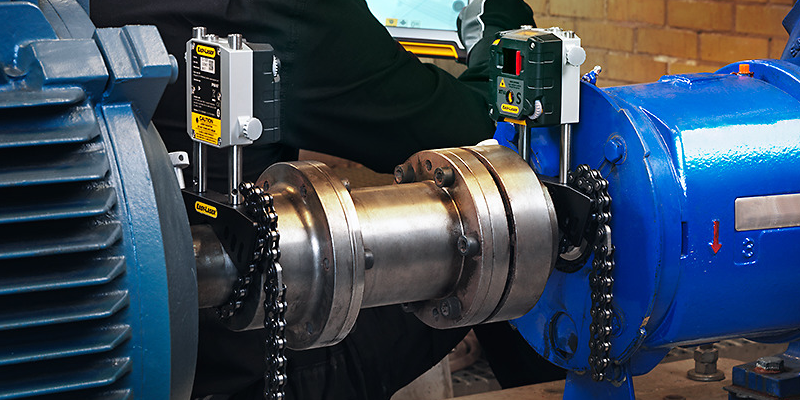

The 2016 EASA (Electrical Apparatus Service Association) Convention in Toronto on June 12-14 was a great opportunity to show off our new Easy-Laser E720 shaft alignment tool to the people attending the show.

The Metro Toronto Convention Centre was full of attendees from around North America.