5 Things You Should Know About Laser Shaft Alignment tools

The following is information written by our partner Easy-Laser® AB and can also be viewed on their Blog here. Enjoy!

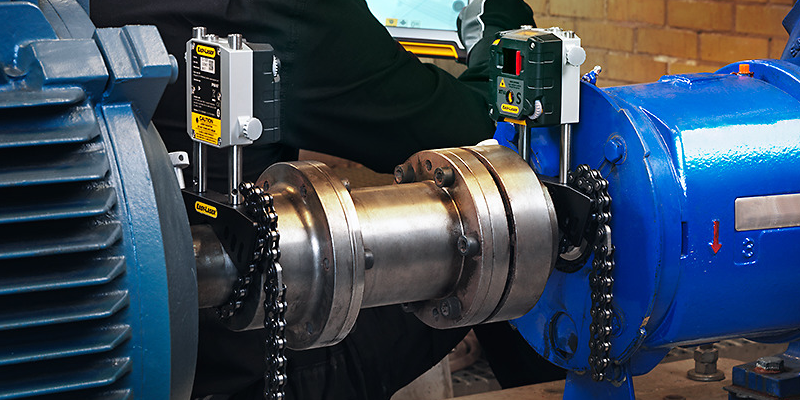

With over 25 years of experience in developing, manufacturing and marketing laser shaft alignment and measurement tools, we thought we would share some noteworthy facts that you perhaps did not know about alignment.

1. Aligning machines is one of the best investments you can make for the environment

How is this possible, you might wonder? Well, if your machines are correctly aligned not only do you save energy, but you also minimize the use of replacement parts. This means reduced energy consumption, required to the manufacturing of those parts. Also, the shipping requirement of these replacement parts disappears. Automatically, the consumption of materials is also reduced. All this makes a large contribution to the environment.

2. A lot of time and money can be saved in engineering workshops

Not only can you help save the environment. Through continuous maintenance and checking of the machinery, also time and money can be saved. A faulty machine caused by misalignment gives problems with several damaged components, extra time for adjusting faulty components or extended machine time to manufacture surplus. A machine that is correctly set saves raw materials, which means that you can predict the production time and meet delivery schedules. Simply, you can produce more at the same time. Now, that is quite a big saving.

3. A laser shaft alignment tool will improve your working environment

It is true. The working environment is improved with reduced leakage and reduced vibrations. A leaking seal in a pump caused by misalignment, means that unnecessary amounts of liquids are spilled. Sometimes these liquids are environmentally harmful. With a correctly aligned machine a serious breakdown with leakage into the working environment can be avoided. Reduced vibrations also means reduced noise level, providing a safer working environment for the staff.

4. Correctly aligned machines reduce the risk of expensive breakdowns and downtime

Except for lower costs for replacement parts, reduced energy, reduced material consumption and saved time, there is another problem you will avoid with a correctly aligned machine: lost production time. With measurement systems for vibration checks and alignment of the machines it is possible to minimize downtime. Less downtime reduces production losses and use of replacement parts – which takes us back to the part where we help save the environment!

5. Measurement and alignment basic problems mirror each other

There are thousands of different applications for laser shaft alignment and measurement tools, in a variety of different industries and various types of machines. But did you know that in many cases the basic version of the measurement systems are extremely flexible, both when it comes to brackets and measurement programs. You will probably find similarities with your measurement and alignment needs. The only real limitation for what you can measure is your own imagination!

Want to know more?

Now, we hope you have picked up one thing or two. But if you want to find out more about laser based shaft alignment and measurement tools, do not hesitate to contact us and we will tell you all about Easy-Laser® Systems!

This article will give you answers to the following questions:

What are the advantages of laser shaft alignment?

How can I reduce my energy consumption with laser shaft alignment?

How can I save money and time with laser shaft alignment?

How does laser shaft alignment improve the working environment?

How can I reduce the risk of expensive breakdowns and downtime?

0 comments

Write a comment