Maximizing Equipment Uptime Through Proactive Maintenance

Regular equipment maintenance is crucial for ensuring maximum uptime and productivity. By adopting a proactive approach to maintenance, businesses can identify and address potential issues before they lead to unplanned downtime or equipment failures.

Implementing comprehensive maintenance programs, such as condition monitoring and predictive maintenance strategies, can help organizations extend the lifespan of their machinery and optimize overall equipment effectiveness. This approach enables better planning, reduces maintenance costs, and minimizes disruptions to daily operations.

Leveraging Data-Driven Insights for Improved Decision-Making

The use of data analytics and smart technologies can provide valuable insights to support more informed maintenance decisions. By collecting and analyzing real-time data from equipment sensors, organizations can gain a deeper understanding of their machinery's performance and condition.

This data-driven approach allows maintenance teams to identify trends, predict potential failures, and proactively schedule maintenance activities. By integrating data-driven insights into their maintenance strategies, businesses can optimize resource allocation, reduce unplanned downtime, and improve overall equipment reliability.

Adopting Industry Best Practices for Machinery Alignment

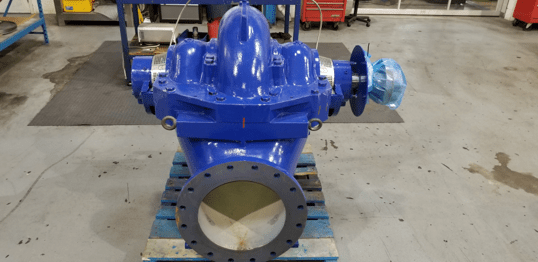

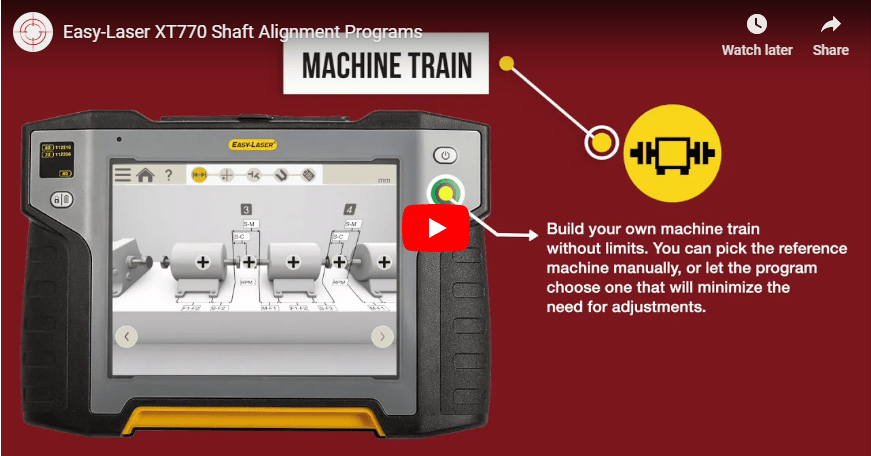

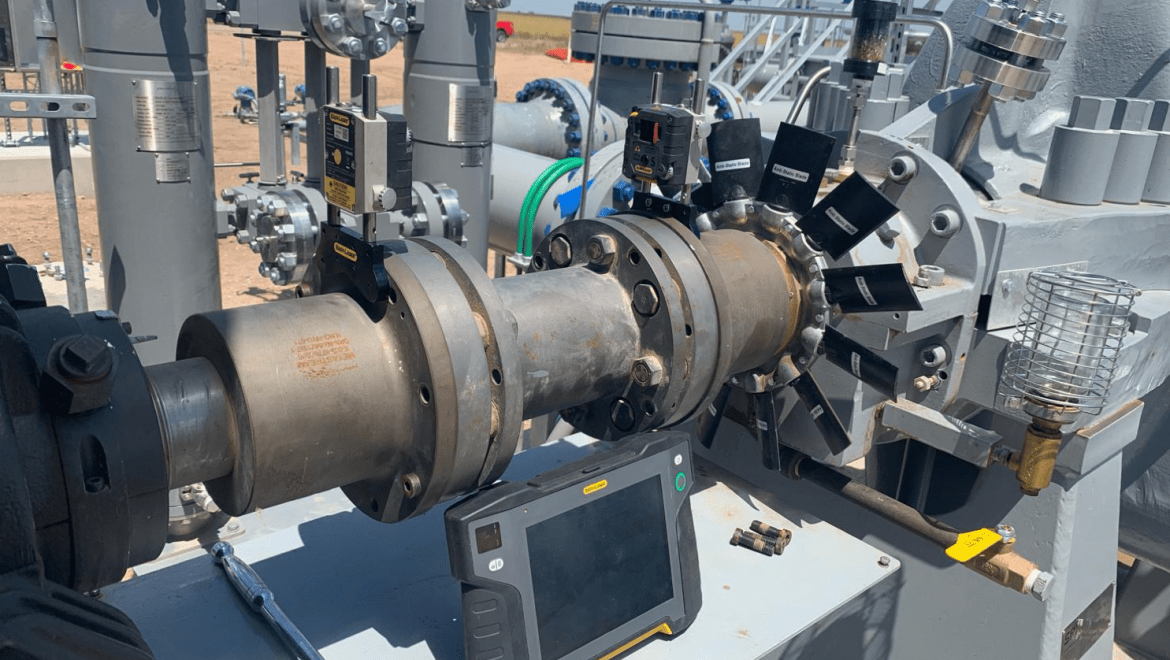

Proper machinery alignment is a critical aspect of maintaining equipment reliability and efficiency. Aligning rotating equipment, such as pumps, motors, and gearboxes, can help minimize energy consumption, reduce wear and tear, and extend the lifespan of the machinery.

By following industry best practices and utilizing advanced alignment tools and techniques, maintenance teams can ensure that their equipment is properly aligned and operating within the manufacturer's specifications. This approach can lead to significant cost savings, improved safety, and enhanced overall equipment performance.

Fostering a Culture of Continuous Improvement

Cultivating a culture of continuous improvement within the maintenance organization is essential for driving long-term success. By encouraging a proactive mindset, providing ongoing training, and empowering employees to identify and address issues, businesses can continuously optimize their maintenance practices.

This approach promotes collaboration, knowledge sharing, and the adoption of innovative maintenance strategies. By fostering a culture of continuous improvement, organizations can stay ahead of industry trends, adapt to changing business needs, and maintain a competitive edge in the marketplace.

Let us review this case study on a common issue when working on a pump and motor alignment done by Brian Franks, Owner and Field Service Technician of JetTech Mechanical (

Let us review this case study on a common issue when working on a pump and motor alignment done by Brian Franks, Owner and Field Service Technician of JetTech Mechanical (