Easy-Laser Shaft Alignment tools offer best Measurement results

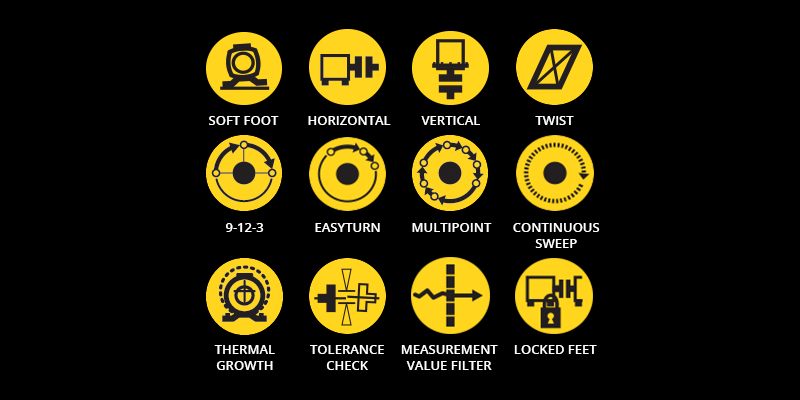

Easy-Laser Shaft Alignment Tools come stocked with many smart laser measurement functions. These smart functions help guide you through the laser alignment process giving you the best possible results. You can use these smart functions with our XT11 display or the free Easy-Laser XT app.

Note: These smart functions are not to be confused with measurement programs that Easy-Laser offers like Horizontal Machines and Softfoot Checks or EasyTurn and Continuous Sweep measurement methods.

![]() Thermal Growth Compensation – Oftentimes, machines expand considerably when moving from a cold to hot operating temperature. The Thermal Growth Compensation function allows the laser shaft alignment tool to calculate the correct shims and adjustment values needed to make adjustment in such cases. Compensation values for the machines are normally supplied by the manufacturers.

Thermal Growth Compensation – Oftentimes, machines expand considerably when moving from a cold to hot operating temperature. The Thermal Growth Compensation function allows the laser shaft alignment tool to calculate the correct shims and adjustment values needed to make adjustment in such cases. Compensation values for the machines are normally supplied by the manufacturers.

Tolerance Check – Measurement results can be checked against pre-defined (industry standard) tolerance tables, the new ANSI Shaft Alignment standard tolerances or values you determine yourself. This allows you to immediately see if the alignment is within the approved parameters, thereby considerably reducing the amount of time spent on alignment

Tolerance Check – Measurement results can be checked against pre-defined (industry standard) tolerance tables, the new ANSI Shaft Alignment standard tolerances or values you determine yourself. This allows you to immediately see if the alignment is within the approved parameters, thereby considerably reducing the amount of time spent on alignment

Measurement Value Filter – An advanced electronic filter function can be used to achieve reliable results even under poor measuring conditions. For example, if you have air turbulence and vibrations from adjacent machines, increase your filter to get accurate measurement results.

Measurement Value Filter – An advanced electronic filter function can be used to achieve reliable results even under poor measuring conditions. For example, if you have air turbulence and vibrations from adjacent machines, increase your filter to get accurate measurement results.

Multiple Sets of Feet – The software can adjust to machine designs of all types: two pairs of feet, three pairs of feet, pair of feet in front of the coupling, etc.

Swap View Function – The swap view function allows you to adjust the position of the motor on the screen to correspond with the position of the machine in front of you, making it easier to understand adjustment directions.

Swap View Function – The swap view function allows you to adjust the position of the motor on the screen to correspond with the position of the machine in front of you, making it easier to understand adjustment directions.

Continue Session – Your latest measurement is always available, automatically saved. Even if your someone turns off the display by accident, you can always go back and continue your alignment.

Continue Session – Your latest measurement is always available, automatically saved. Even if your someone turns off the display by accident, you can always go back and continue your alignment.

Built-in Help Manual – The XT11 display (or app) includes a searchable User’s Manual which opens the right chapter depending where in the process you are. This makes it quick and easy to find the answer to your user questions.

Built-in Help Manual – The XT11 display (or app) includes a searchable User’s Manual which opens the right chapter depending where in the process you are. This makes it quick and easy to find the answer to your user questions.

Locked Feet – Lock any pair of feet on the machine. Used when aligning base-bound or bolt-bound machines.

Locked Feet – Lock any pair of feet on the machine. Used when aligning base-bound or bolt-bound machines.

Wide Live Adjustment – Adjust with live values using expanded sensor position ranges in the H and V position. Adjust with live values also when measuring units are positioned up to 44° from absolute V and H position.

Wide Live Adjustment – Adjust with live values using expanded sensor position ranges in the H and V position. Adjust with live values also when measuring units are positioned up to 44° from absolute V and H position.

Select Machine Image – Choose from different 3D machines to portray your own machinery on either side of the coupling.

Select Machine Image – Choose from different 3D machines to portray your own machinery on either side of the coupling.

Select Coupling type – Choose method depending on coupling type: short flex, spacer shaft.

Select Coupling type – Choose method depending on coupling type: short flex, spacer shaft.

![]() **360Live Adjustment – Allows you to align the machine using the measurement units positioned at any angle around the shaft. This is useful when it is difficult to rotate the shaft, or when machine components are in the way.

**360Live Adjustment – Allows you to align the machine using the measurement units positioned at any angle around the shaft. This is useful when it is difficult to rotate the shaft, or when machine components are in the way.

*excluding the 360Live Adjustment function

**only available in the advanced XT770 Shaft Alignment tool.

0 comments

Write a comment