Starting a Condition Monitoring Program and Keeping it Simple

Condition-Based Maintenance has been defined as: Maintenance based on the condition of an asset. Asset: An item of value. Condition: The state of an item.

Condition Monitoring is the art of monitoring your equipment health by taking simple measurements of the machines performance, much the same way a Doctor will check (measure) your health by checking your pulse, temperature, blood pressure etc.

If these measures are abnormal, the doctor may suggest that they continue to take measurements but maybe more often. Or based on the first set of readings he may recommend some process changes such as, better diet, more rest, etc. He bases his decisions on known values or a standard, on scientific research, or experience from training. Thankfully the medical profession has a good understanding of what is normal and what is not.

If these measures are abnormal, the doctor may suggest that they continue to take measurements but maybe more often. Or based on the first set of readings he may recommend some process changes such as, better diet, more rest, etc. He bases his decisions on known values or a standard, on scientific research, or experience from training. Thankfully the medical profession has a good understanding of what is normal and what is not.

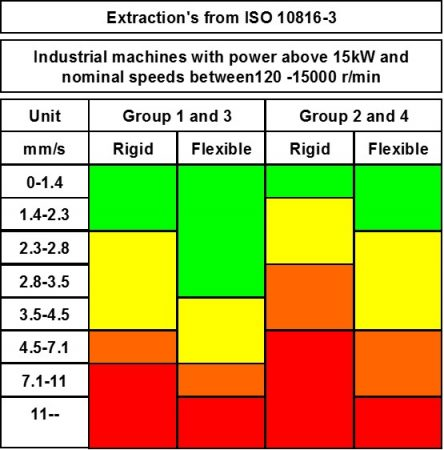

You can also compare measurements to a known standard such as a bearing chart for instance, or the ISO standard for vibration (see chart left). You can use the equipment manufacturer’s specification, or the history record of the piece of equipment itself as a comparison.

If you were measuring the current draw and the outlet flow of a pump and could see that the draw was increasing, yet the outlet flow was decreasing, as compared to the measurements you had taken over the previous months, you would be right in assuming that the condition was deteriorating and that some maintenance was due for the pump. This is assuming of course that all the other variables had stayed the same such as the material the pump was pumping was the same. Flow and current cannot be measured on all the machines so you have to choose a measurement parameter that is more suitable for the majority of your equipment. Which technology you use will depend on the equipment you have. However, vibration measurement is the most versatile and gives the most information which is why it is the most used measurement parameter.

Remember, what we are trying to do is to take a simple measurement such as vibration, and monitor (watch) the value. We can then react to any changes. The easy way to do this is by trending the measured value. We are trying to keep it a simple process. This is not vibration analysis. Vibration analysis is too time consuming and requires expert interpretation. However, if the trend is climbing we can then choose to bring in the expert.

PHOTO (right) – A vibration reading is taken with an X-Viber instrument.

PHOTO (right) – A vibration reading is taken with an X-Viber instrument.

We, on the other hand, are looking for a simple number that we can trend over a period of time; a number that can tell us that one (1) is good and two (2) is bad. We all know that to control a process we must measure it. One of maintenance most important processes is its Preventive Maintenance program (PM’S). By adding measurement we add more control. This is a great opportunity to combine these two programs together.

I believe that the way we do PM’s has changed. We now use detection instruments during the process. By using simple instrument such as ultrasonics or vibration monitoring we can unobtrusively monitor our equipment as part of the PM. I guess you can call it Condition-Based Maintenance, but to me it’s still a calendar based PM. The fact that I now use ultrasonics to listen to the machine instead of a screw driver doesn’t change what I am doing. The change is the technology that I use. Whether we call it Preventive Maintenance or Condition-Based Maintenance, I don’t think it’s important. What’s important is that it is done on schedule, that it is fully comprehensive and most importantly condition measurements are taken before and after the PM or work has been completed.

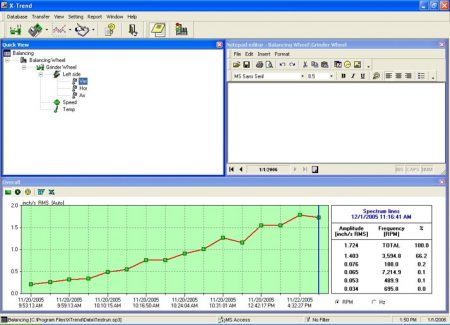

PHOTO (left) – Using simple software you can create a route and trend the vibration results.

PHOTO (left) – Using simple software you can create a route and trend the vibration results.

I would have a PM technician as the owner of this process. I would not use him to complete any of the work that was deemed necessary but he would be responsible to commission the machine back into service as well as to take and trend the measurements.

He can then compare the measurement results to the last PM measurement, as well as to the measurement he took when the machine was on line. If there is a change in the result he can ask the question: why is there a difference? This is very important because if he keeps asking why and looking for solutions such as shaft alignment, balancing, etc. he is on the path of machinery reliability improvement.

0 comments

Write a comment