Machine Bases – Flatness Case Study

Here we are using a laser shaft alignment tool and we have added a D22 swivel laser that can sweep across the base in order to measure flatness in both X and Y coordinates. Before we show you the results let us first show you how we plan to measure. Although the base appears to be two long rails the motor only sits on the shim packs which are positioned under the mounting pads on the motor.

PHOTO (right) – Base flatness measurement with Easy-Laser alignment measurement system.

PHOTO (right) – Base flatness measurement with Easy-Laser alignment measurement system.

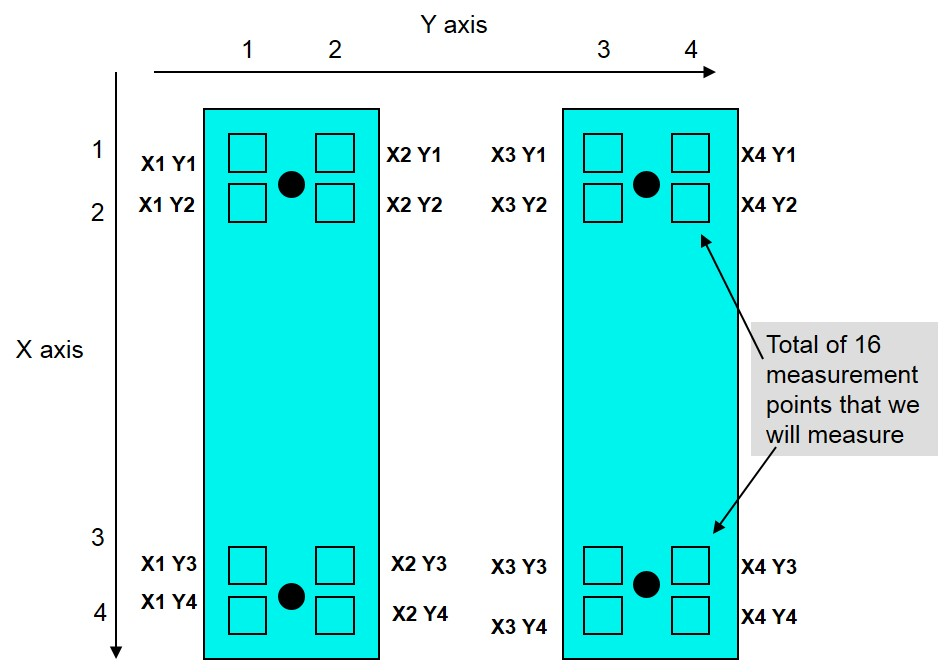

This means that we only have to measure around each of the bolt holes. If we measure at each corner of each bolt hole we will have an area of about 5” x 5” sq. So first we set up a grid.

ILLUSTRATION (above) – Measurements were taken on each corner of each of the four foot positions.

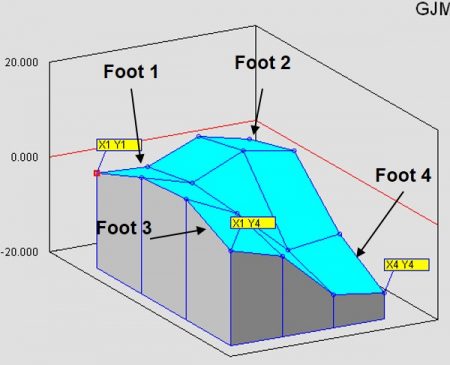

PHOTO (below left) – After the measurements were taken, the information was transferred to the EASY-LINK software program and a 3D line graph was produced.

GRAPH (below right) – This is the 3D graph that the software uses to show you a pictorial view of the measurement results. The centre is colored but you can still see the two rails down each side showing you that #2 foot is high and the #4 foot is low.

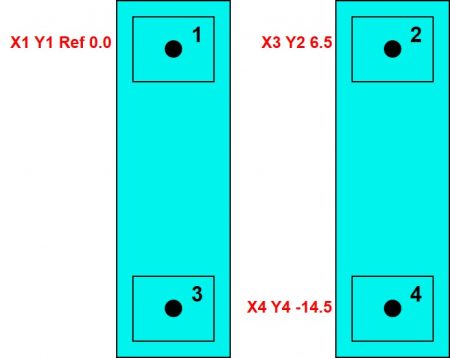

This is the full report you get and I have numbered the feet. I have also highlighted (in red ) the reference point and the highest and lowest measurements that were taken.

This is the full report you get and I have numbered the feet. I have also highlighted (in red ) the reference point and the highest and lowest measurements that were taken.

Easylink 2.2 P31

Registered to John Lambert, Benchmark Maintenance Services Inc.

Filename: GJM

Date: 08.11.13

Time: 12:10

Program: Flatness

Unit: thou

Serial: 38335 / 38139

Temp: 75.0F

Pos Ref Value

——————————————– —————-

X1 Y1 Ref 0.0

X1 Y2 4.5

X1 Y3 5.5

X1 Y4 0.0

X1 Y4 0.0

X2 Y1 -0.5

X2 Y2 1.5

X2 Y3 0.5

X2 Y4 -3.0

X3 Y1 4.0

X3 Y2 6.5

X3 Y3 -9.0

X3 Y4 -13.0

X4 Y1 1.5

X4 Y2 4.5

X4 Y3 -7.5

X4 Y4 -14.5

——————————————– —————-

Max 6.5

Min -14.5

Peak-Peak 21.0

Average level -1.2

Standard dev 5.1

——————————————– —————-

Flatness Rms 4.4

If you are involved with vibration analysis of electric motors and you see high readings of rotor bar frequency, 2x line frequency (exactly 120HZ), etc. you may want to consider that the motor casing is under strain. If you have a look at the picture of the base again you can see that it is a well made base that was machined flat after being fabricated but my guess is that it was not stress relieved and it has twisted over time.

The D525 system and D22 Swivel Laser was used to measure the flatness of this base.

The newer version of this would be the E920 Geometric system.

0 comments

Write a comment