Easy-Laser release new XT660 Shaft Alignment tool and XT190 BTA pulley Alignment tool

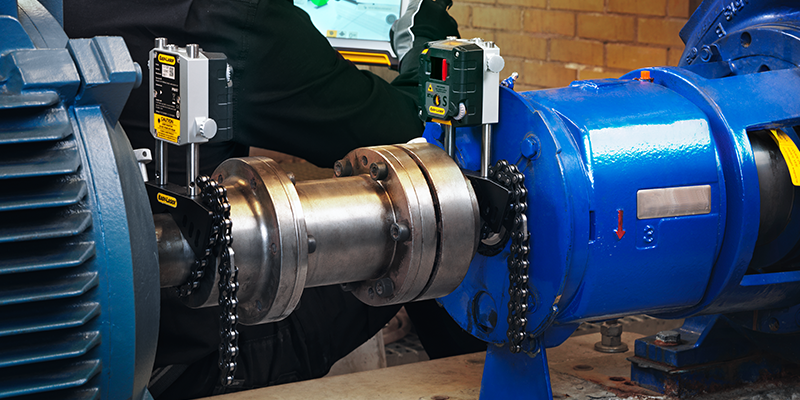

The Easy-Laser® XT660 is here!

We are happy to announce the next system in Generation XT, the Easy-Laser® XT660 shaft alignment tool, which builds on Easy-Laser’s groundbreaking cross-platform technology. You can use your own iOS/Android phone or tablet as a display unit, or purchase the watertight, rugged XT11. Or why not do both? The app is free to download, both now and in the future. The choice is yours!

The XT660 shaft alignment tool offers measuring units with dot laser. You now have access to advanced measurement methods, such as continuous sweep and multipoint. You can perform measurements on larger machines and over longer distances. You have even greater potential to perform correct machine installation right from the start, by checking the twist/flatness of the base. In short, Easy-Laser® XT660 shaft alignment tool is the system for machine aligners who see the bigger picture.

Other new features in the XT Laser Alignment app:

- It is now possible to set intervals and time periods in order to register measurement values automatically in the Value program.

- It is now also possible to e-mail measurement reports from the XT11.

- New program: digital alignment of sheaves/pulleys (accessory required)

- Improved graphics and interface.

Note that the other new features (above) in the app will also benefit users of the XT440 shaft alignment tool. The new version of the app is expected to be available at the AppStore/GooglePlay and on our website at the beginning of October. Click here for more information on the XT660.

Easy-Laser® XT190 BTA

Easy-Laser is now also launching their new digital tool for belt drive alignment, the Easy-Laser® XT190 BTA pulley alignment tool. It can be used as “stand-alone” system with the built-in display, or you can download the free app for your phone or tablet. You can follow the adjustment of the machine in real time from the side of the machine where you are making adjustments. Other benefits include access to shim values, checking against the manufacturer’s alignment tolerances and the potential to document the alignment. You naturally also enjoy the same opportunities with our own display unit, the XT11! Click here for more information on the XT190 BTA pulley alignment tool.

0 comments

Write a comment