Local Utilities Company knows about Extending a Machines Life Expectancy

Recently, BENCHMARK PDM trainers were called to go a couple of hours northeast to a Utilities company that needed some on-site training for an Easy-Laser shaft alignment tool purchased not long ago. Usually, on-site or “on the job” training sessions aren’t offered because it is hard to teach each tradesmen, mechanic or millwright the specifics of the shaft alignment tool and then do it real-time with them retaining all of the information.

The trainers asked that the day be split up into an in-class morning session and the afternoon would be on the site training of what was learned in class. To have a good understanding and practice what was learned first before trying it “on the job” was very important, especially when in real world situations there is a potenital for something to go wrong. So the morning was spent on the machinery installation up-front work, pre-alignment checklists, basic shaft alignment principles and laser theory (see photo below).

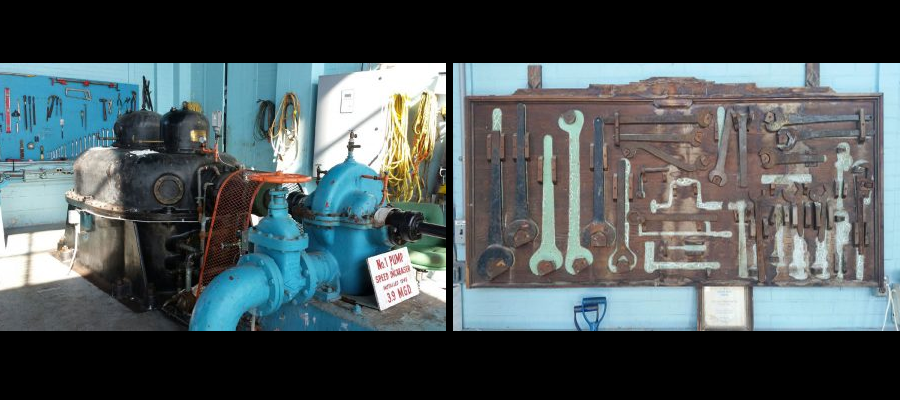

In the afternoon they were now ready to go on-site to use the laser alignment tool on some very old machines. Pictured below left are some of the machines that were to be measured and aligned using the customers recently purchased laser shaft alignment tool. In the bottom right of the photo there is a sign with a written installation date of 1945! Pictured below right are some of the older tools that would have been used for machinery installation over the years – just for show!

Using the customers’ Easy-Laser E540 shaft alignment tool, the trainers reiterated what they taught the millwrights in class and went to work on some very old equipment. “You probably haven’t seen rotating machinery like this before,” one of the mechanics said to the trainers. And he was right. The equipment was old and different then most motor to pump set ups (see photo below). Before using this laser shaft alignment tool, the company had been using dial alignment and dial gauges and before that straightedge/feeler gauges for their alignment needs. Whatever the method, this company knew about giving their machines (and assets) the longest life possible. They had given this equipment about 70 years of life and still going strong!

Photo above: open coupling shaft to shaft alignment.

0 comments

Write a comment