Shaft Alignment tools

Easy-Laser Alignment Systems

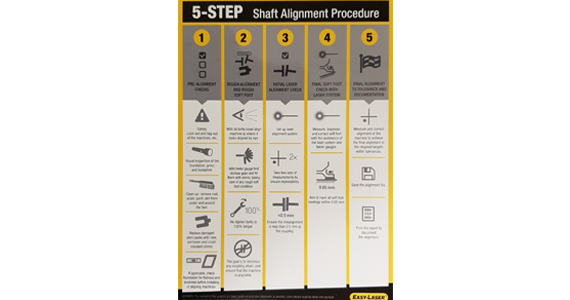

Laser shaft alignment tools were not always used when aligning two or more machines. The traditional methods of using straightedge/feeler gauges and/or dial indicators (or dial alignment systems) were used for many years – and at some companies, still are!

These days, the most common shaft alignment methods are when using laser shaft alignment tools. They offer customizable reports, with AS Found and AS Left results, softfoot measurements that were taken, and the ability to add custom notes on the alignment work. Our laser shaft alignment tools from EASY-LASER do all of this and more. You can even take photos and Infrared images of the machine using the new display unit from our XT Generation of laser shaft alignment tools. When finished, you can e-mail the report from the display to your customer or yourself so you can add it to the machine history.

Easy-Laser shaft alignment tools offer so much. Scroll down below to find out a bit more on the differences between our new Generation XT Series of shaft alignment systems. Or click on one of our tools below to find out more on each one.

EASY-LASER XT770 Shaft Alignment Tool / XT770GEO

The XT770 shaft alignment tool measuring units utilize dual beam dot-type laser technology with 2-axis square PSD surfaces making it possible to measure larger machine spans and the most advanced alignment applications.EASY-LASER XT660 Shaft Alignment Tool

The XT660 shaft alignment tool measuring units utilize dot laser technology. This makes it possible to measure larger machines and longer spans than line laser systems. It also provides higher accuracy when …EASY-LASER XT550 EX Shaft Alignment Tool

The Easy-Laser® XT550 Shaft Alignment Tool measuring units and the ecom Tab-Ex® tablet are approved in accordance with the latest ATEX directives – this means the system is intrinsically safe for explosive or hazardous environments …..EASY-LASER XT440 Shaft Alignment Tool

The XT440 shaft alignment tool is the first member of our Generation XT shaft alignment systems, built on Easy-Laser’s new cross-platform technology. This allows you to display data different handheld….EASY-LASER E710 Shaft Alignment Tool

The Easy-Laser E710 shaft alignment tool is our Professional shaft alignment tool that gives you the ability to perform any type of shaft alignment application. Perform precision shaft alignments up to 20 meters (66 feet) with Dual-Axis…EASY-LASER Shaft Alignment Tools – Wind Power

Large forces are in action in a wind turbine. The safety of the maintenance technicians is therefore of the utmost importance. With the Laser Shaft Alignment Tool Wind Power line of Easy-Laser® shaft alignment systemsThe most common issue for the alignment technician when doing horizontal shaft alignments is being bolt-bound or base-bound. All of our XT laser shaft alignment tools including the XT440 shaft alignment tool, XT550 Ex shaft alignment tool, XT660 shaft alignment tool and XT770 shaft alignment tool will give you simple alternatives for this problem. For example, if you cannot move your machine to the left because you are up against the hold-down bolt, you can simply lock/fix this foot and move a combination of the other feet that give you the best option.

Mid-range to high end Laser Shaft Alignment tools like the XT660 shaft alignment tool and XT770 shaft alignment tool will also give different measurement methods such as Continuous Sweep which is one continuous measurement – great for eliminating backlash in a coupling. Another one is Uncoupled Sweep method which is especially useful when only one (or none) of the shafts can be rotated manually and there is no coupling connected. Or why not Multipoint for more critical machinery like turbines. Our top end system, the Easy-Laser XT770 Shaft Alignment Tool can access advanced measurement functions like cardan shaft alignment (universal joints), Machine Train (multiple couplings) alignment, and EasyTrend for offline to running machinery movement, an excellent program to determine the thermal growth of a machine! They can even assess the quality of the measurements you have taken! The classic Easy-Turn measurement method is available with all EASY-LASER systems which only needs 40 degrees of rotation. For more info on the five different measurement methods available, click here. And there is more, a lot more available with Generation XT, that make the machine’s installation easier.