You cannot say it’s a new industry because its been around for quite some time however, you can call it a growth industry because yes, it’s still growing. In fact, I can see it getting bigger. My reason for this is that I can see some remote communities taking advantage of this technology, technology that is improving with better power storage and other modern machinery. I can also see some large manufacturing plants generating their own power to save on the costs because as we know, power is expensive to buy. I cannot say that we are there yet but as costs come down it looks like a viable alternative to what we do now in many cases.

Read more

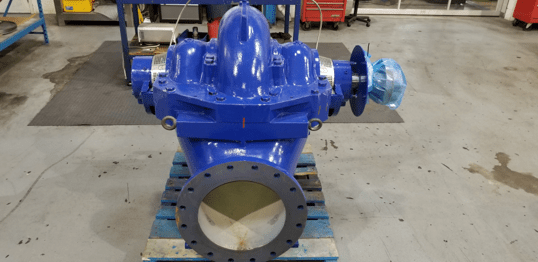

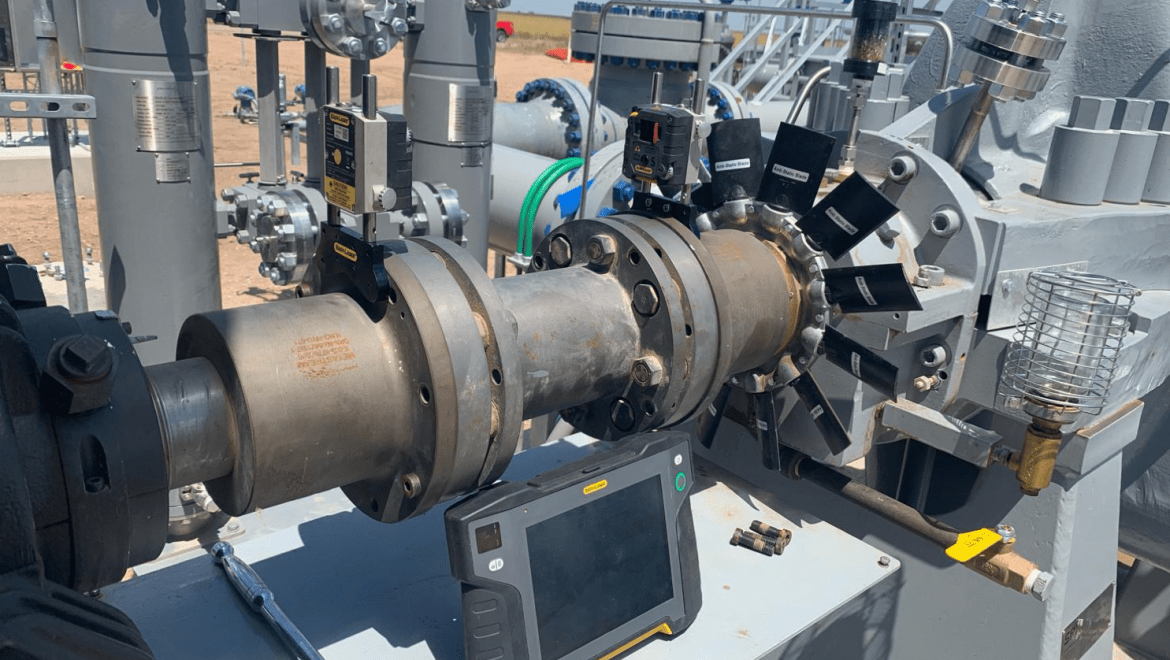

Let us review this case study on a common issue when working on a pump and motor alignment done by Brian Franks, Owner and Field Service Technician of JetTech Mechanical (

Let us review this case study on a common issue when working on a pump and motor alignment done by Brian Franks, Owner and Field Service Technician of JetTech Mechanical (